Taking digitalisation one step at a time will offer a resilient, safe and sustainable maritime ecosystem for all those involved in the supply chain argue Mikael Lind, Richard T. Watson, andWolfgang Lehmacher.

Achievement of an efficient, resilient, safe, and sustainable maritime ecosystem is a multi-year, multi-stage project that requires a sequence of interlocking actions. Attainment of the ultimate goals of any major project requires a series of intermediate steps where accomplishment of one step establishes the foundations for the achievement of subsequent steps.

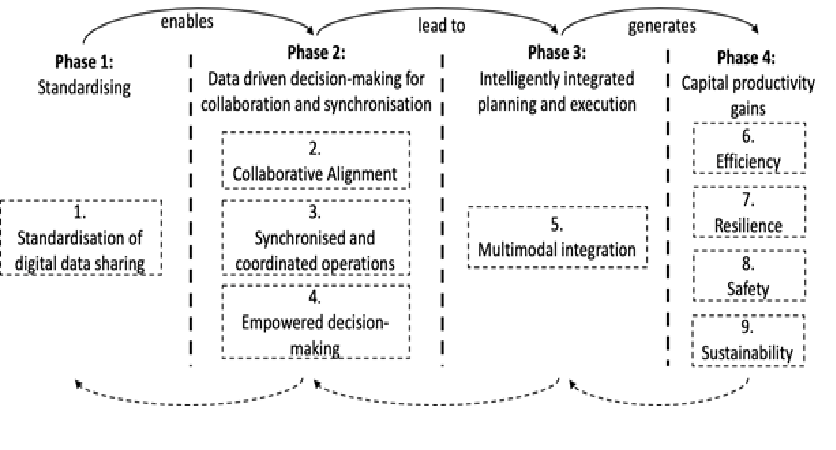

A number of different enablers support the application of Maritime Informatics to create higher levels of maritime efficiency, safety, environmental sustainability, and resilience. In this concise article we identify these enablers and map out how they link to each other in cause-effect relationships (see the following diagram). We also show with a dotted line how lessons learned during each of the phases shown in the diagram can inform improvements in the prior phase.

Figure 1: Maritime Informatics enablers and expected effectsA steady flow of benefits requires that the phases are chunked into specific concrete usable outcomes. For example, a digital standard for a discrete element of operations might be prioritised to enable achievement of its benefits in subsequent phases. It is expected that the four phases in the diagram will be continually iterated as new standards, models, and tools becoming available or existing ones are modified to meet changing customer expectations as well as business, societal, and environmental needs.

Phase 1: Standardising

1. Standardisation of digital data sharing

Digital data sharing standards are a prerequisite for higher performance. As the economy moves ahead with its digitalisation efforts, every industry’s players need to share data to co-ordinate and synchronise their activities and integrate into the overall ecosystem. Without industry standards this is unwieldy, given the international and self-organising nature of the fragmented shipping industry. No shipping company wants to deal with a different data exchange standard and set of data requirements for each port or terminal. But this is a current reality.

All objects (for example, containers), all interactions (for example, between ships and pilots), and all services (for example, customs clearance) need standard digital data descriptions and processes to grease the path towards interoperability.

Digital standards will sit on the top of a global communications layer (for example, based on maritime satellites, 5G) to provide harmonised global communications within the maritime industry and between the industry and other transport providers. Universal standards, such as the metric system, reduce the friction of commerce, and the shipping industry can eliminate its current brake on profits by pursuing standardisation across the industry, starting with aligning all major ports.

Standards enable interoperability across systems and connectivity between systems. APIs and XML are frequently critical foundations for seamless integration. APIs enable authorised parties to extract relevant information from their partners’ systems, and XML-based standards enable messages to be read and interpreted in a uniform manner within an ecosystem.

Currently, there are intergovernmental and industry driven initiatives engaged in securing standards for the maritime industry. Standardisation enhances interoperability, which is an enabler of integrated multimodal operations as a basis for high performance in a self-organising ecosystem.

Phase 2: Data driven decision-making for collaboration and synchronisation

2. Collaborative Alignment

Standardised data sharing is a precondition for collaborative alignment as standardisation allows achievement of a common situational awareness among parties who need to co-ordinate their actions to transact a service. For example, a ship berthing might require collaborative alignment among a ship’s captain, tug masters, and linesmen. Such operations are often subject to continual re-planning due to disruptions, such as a ship’s delayed departure from the immediately prior port or an unexpected change of weather.

Common situational awareness, which is critical to the many collaborative alignments in a port visit, requires real-time data sharing among the involved parties within the specific time-window spanning the necessary planning horizon before interaction.

Ports have to continuously deal with abrupt changes, such as those caused by the late arrival of a vessel, unanticipated shortages of labour and equipment, like chassis and containers, and highly volatile cargo volumes.

Digital twinning is one relatively inexpensive option for preparing to deal with abrupt change. Digital twinning assists in understanding complex business problems and identifying effective interventions and appropriate scenarios for action. Data are necessary to calibrate a digital twin, but there must first be an investment in human and organisational capital to create and maintain a digital twin.

3. Synchronised and co-ordinated operations

During a port call, there are many operations that need to be synchronised, such as:

- A pilot is at the pilot boarding station when a ship arrives

- Tugs and a ship meet up at the same geographical location at the same time

- Linesmen are stationed at the designed berth at the arrival time to secure berthing of a ship

- Sufficient stevedores are assigned to handle expeditiously a berthed ship’s cargo.

Beyond the port, there are numerous situations where synchronisation and co-ordination are needed when resources are shared, such as a busy narrow waterway. Synchronisation failures can result in unnecessary waiting times, extended turn-around times, under-utilisation of resources, and in the worst case a collision.

We envision the transfer of appointment economy principles to shipping in the area of berthing. We foresee general adoption of the booking of berths in advance of a port visit and a supporting infrastructure for berthing rights trading to cater for variations in arrival times.

For example, when a ship recognises it will be a late arrival, there could be a marketplace where it can sell its ‘right to berth’ at the previously planned arrival time. A marketplace can improve planning and reliability by balancing a firm commitment to a berthing slot, and at the same time provide some flexibility to handle unanticipated disruptions. The ultimate goal is to raise the level of predictability for sea transport clients.

Successful synchronisation requires empowered decision-making to ensure the collaborative alignment of the necessary resources.

4. Empowered decision-making

Decision-making is the central activity of nearly every organisation, and data-driven organisations deliver higher quality decisions. Access to appropriate real-time digital data streams (DDS) and databases has become critical for both operational and strategic decision-making. However, if shared data are not in a standard or common industry format then decision-making is just as hampered as a conversation which involves parties that speak different languages.

The various forms of data analytics (descriptive, predictive, explanatory, diagnostics, and predictive) and machine learning all have the potential to empower decision-making. Perhaps the greatest opportunity for Maritime Informatics is in the area of resource allocation by applying prescriptive analytics to typical problems, such as cargo unloading, to minimise cost.

Phase 3: Efficiency gains from integrated planning and execution

5. Multimodal integration

While 90 percent of the goods transported globally spend days, weeks and months at sea or on a waterway, many shipments start and finish their journey by land. Coordination across and within sea transport is often inefficient, and some cargo owners institute time buffers to meet their clients’ service expectations. The steps taken in phase 2 create the capacity for seamless integration between modes of transport by facilitating situational awareness across a cargo’s entire journey from producer to consumer.

Multimodal integration requires a focus on the goods being transported rather than a sub-optimised leg by leg focus and transition between modes. Alignment of modes through coordination and synchronisation, as established by the prior phase, will support integration, enable tracking of shipment progress, and dynamic rescheduling as required.

Phase 4: Capital productivity gains

The ultimate goal of all organisations is to raise their capital productivity. We now discuss the four main areas targeted by the shipping industry.

6. Efficiency

All executives are well aware of the need for efficiency in the use of economic and human capital. They are familiar with the use of information systems for efficient transaction processing and data collection.

Empowered decision-making and standardised digital data sharing are key to harvesting gains from autonomous and remotely supported operations. Automated operations, both at sea and onshore operations, such as for cargo operations and mooring, will require extensive digital innovation for their full realisation.

7. Resilience

An increase in adverse weather is an acknowledged consequence of global climate change. Covid-19 has demonstrated the disruptive power of a pandemic. With increasing population and urbanisation, we should prepare for similar outbreaks in the future, as well as for a rising number of natural disasters. These perturbations have a tremendous impact on productivity, as we have seen with the global drop in economic growth following the Covid-19 outbreak.

A poorly handled disruption can destroy a business, but careful preparation and rehearsal can identify key factors and unknowns for consideration and will support a more resilient response by companies and governments.

8. Safety

A ship, its cargo, and its crew are major economic and human capital investments. The industry has long been concerned with partial or complete loss of any of these key resources. Increased safety is therefore a particularly important Maritime Informatics goal because it will help to preserve key capital, especially human life. The adoption of interoperable data standards for onboard equipment is essential for reducing accidents by improving the quality of alert signals and thus decision making.

9. Sustainability

The shift to renewable energy sources is often seen as the main pathway to a sustainable society, but it has important partners that are often overlooked – energy efficiency and capital productivity. The data analytics component of Maritime Informatics is concerned with these two areas. It is aimed at doing more with less energy and less capital of all forms. For example, machine-learning based predictive maintenance can facilitate the shift from time-based to the less wasteful condition-based maintenance.

A circular economy includes the principles of sharing, reuse, remake and recycling, and these principles are another opportunity to raise capital productivity. For example, when ships are scrapped there are opportunities for the reuse of components, provided the ship has been designed for disassembly and all components are digitally identified and described in a database. Additionally, there needs to be a marketplace for these accurately described components to maximise their value. The same possibilities exist for port equipment. Digital standards for component identification and description and shared systems of record enable large-scale circular supply chains.

High on the maritime agenda is the transformation of shipping to fossil-free energy sources for both construction and operations. This conversion requires that fossil-free fuel is widely available at major ports throughout the world. This can be facilitated by a global digital marketplace to enable efficient balancing of supply and demand so ships can plan with certainty when and where to refuel.

Realising the path

All maps and their associated paths may look simple, but most journeys face a reality that is highly complex, which hinders creation of a more productive industry. The Maritime Informatics map presented in this article builds on the fundamental viewpoint that maritime transport does not exist in isolation. Cargo owners and transport co-ordinators desire seamless integration in the global transport chain. In this effort the core focus areas identified in phases 1-3 are necessary for this transition forming the basis for gaining capital productivity (phase 4).

However, and most importantly, digitalisation is just an enabler. It is probably the most important means of achieving the ultimate goal of increased capital productivity. All actions should be judged in terms of how they contribute to raising capital productivity. The framework presented in this concise article helps you to identify waypoints on the capital productivity quest. It can help organisations and the industry position project initiatives taken at an organisational, national, regional, and international level.

Acknowledgement

We are grateful for the invaluable input provided by Hanane Becha (UN/CEFACT), Jillian Carson-Jackson (The Nautical Institute), Xiuju Fu (A*Star/IHPC), Jan Hoffmann (UNCTAD), Michalis Michaelides (Cyprus University of Technology), André Simha (Mediterranean Shipping Company (MSC)), Sukhjit Singh (University of Trinidad and Tobago), Robert Ward, Secretary-General emeritus of the International Hydrographic Organisation, and Phanthian Zuesongdham (Hamburg Port Authority), in the development of this article.

About the authors

Mikael Lind is the world’s first Professor of Maritime Informatics and is engaged at Chalmers, Sweden, and is also Senior Strategic Research Advisor at Research Institutes of Sweden (RISE). He serves as an expert for World Economic Forum, Europe’s Digital Transport Logistic Forum (DTLF), and UN/CEFACT. He is the co-editor of the first book of maritime informatics recently published by Springer.

Mikael Lind is the world’s first Professor of Maritime Informatics and is engaged at Chalmers, Sweden, and is also Senior Strategic Research Advisor at Research Institutes of Sweden (RISE). He serves as an expert for World Economic Forum, Europe’s Digital Transport Logistic Forum (DTLF), and UN/CEFACT. He is the co-editor of the first book of maritime informatics recently published by Springer.

Richard T. Watson is a Regents Professor and the J. Rex Fuqua Distinguished Chair for Internet Strategy at the University of Georgia. He has written books on Data Management; Electronic Commerce, Internet Strategy, Energy Informatics, and Capital, Systems, and Objects, he is the co-editor of the first book of maritime informatics, and has published nearly 200 journal articles.

Richard T. Watson is a Regents Professor and the J. Rex Fuqua Distinguished Chair for Internet Strategy at the University of Georgia. He has written books on Data Management; Electronic Commerce, Internet Strategy, Energy Informatics, and Capital, Systems, and Objects, he is the co-editor of the first book of maritime informatics, and has published nearly 200 journal articles.

Wolfgang Lehmacher is operating partner at Anchor Group. He is chairman of the board of directors of Logen, member of the board of directors of Roambee, strategist Thematiks Supply Chain Innovation Network, advisory board member of The Logistics and Supply Chain Management Society, ambassador of The European Freight and Logistics Leaders’ Forum, and founding member of the think tanks Logistikweisen and NEXST.

Wolfgang Lehmacher is operating partner at Anchor Group. He is chairman of the board of directors of Logen, member of the board of directors of Roambee, strategist Thematiks Supply Chain Innovation Network, advisory board member of The Logistics and Supply Chain Management Society, ambassador of The European Freight and Logistics Leaders’ Forum, and founding member of the think tanks Logistikweisen and NEXST.

Hotline: 0944 284 082

Hotline: 0944 284 082

Email: manager@vykhang.com.vn

Email: manager@vykhang.com.vn

VN

VN